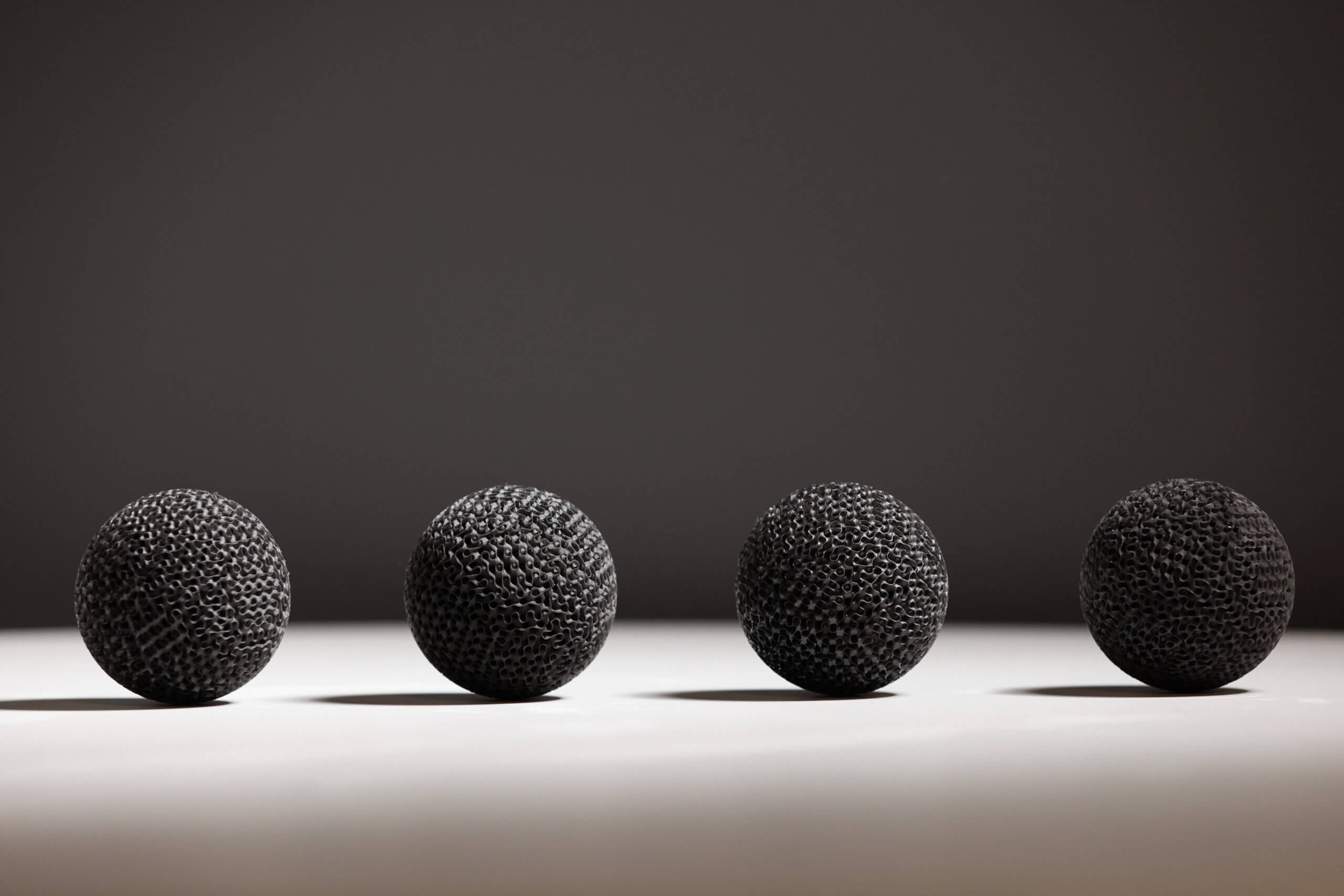

Looking to explore a new application?

Fortify’s FLUX Series printers are able to print and process viscous and filled photopolymers for scalable, engineering applications. Combined with Fortify’s proprietary FLUX Developer software, new materials can be onboarded to explore new applications in a matter of days, dramatically accelerating time to market.