Written by Karlo Delos Reyes, VP of Applications

Fiber alignment is a key driver in the mechanical performance of composite parts. In the world of injection molding, where fiber alignment is typically dictated by shear forces and resin flow, molders are beholden to intricate design techniques and complex gating strategies to influence fiber alignment. This is a complex process with many tradeoffs.

The effect of fiber orientation on properties such as tensile strength, and stiffness are well documented. The mechanical properties of a part are strongest along the axis of the fibers and degrade as orientation moves off that axis.

Credit: Semantic Scholar

Because fiber alignment is critical to achieving optimal material properties, many groups have looked into methods of aligning fiber in an additively manufactured part. The most commonly used method is to compound an engineering thermoplastic (FFF feedstock) with short fibers and utilize the shear forces exerted upon the bead during extrusion to orient fibers along the extrusion direction. This method, however, has many limits, as complex alignment paradigms are not so easy to employ. This method also has limitations typical of FFF, such as extreme anisotropy.

Fortify is rising to this challenge – creating additive manufacturing solutions to enable engineering-grade material properties with control over fiber alignment.

The first solution that Fortify’s engineers have developed is CKM (Continuous Kinetic Mixing; Read more about the CKM technology here). This system allows for the incorporation of engineering additives, such as fibers, into a photopolymer. This system gives FLUX 3D printers the ability to process and print highly viscous, filled materials.

Fluxprint, a module that enables the printer to orient fibers during the DLP 3D printing process, takes this a step further. Fluxprint utilizes custom electromagnets to apply a magnetic field across the build area during printing to align reinforcing fibers. This enables an increase in mechanical performance of 3D printed parts for applications that undergo stressful conditions, such as injection mold tooling.

The ability to align fibers optimally throughout a part is exciting, but that ability does have a cost. The challenge of determining optimal alignment and then embedding that information into a print file is a new step in the additive manufacturing workflow. In some applications that extra effort is well worth the effort.

For the mold tooling application, Fortify engineers have determined that a predetermined fiber orientation scheme throughout the part is the best approach. This provides the benefits of fiber alignment without the overhead of programming.

Fortify developed a programmed alignment scheme for injection mold tools that thread the needle between optimal material properties and manufacturing time.

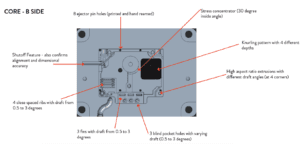

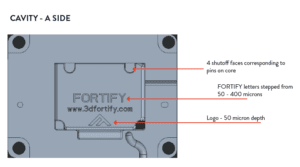

To validate and perfect the approach, Fortify’s applications engineers designed a developmental mold geometry to serve as a “torture test” that is meant to quantitatively assess the nuanced difference in mold performance between materials, alignment schemes, and processing conditions.

This test geometry contained over 30 unique features that simulate various injection molded geometries, such as tall extrusions, fine textures, blind pockets, and shut-offs. To acquire the most usable data from this tool, the engineers included varying levels of difficulty for each of these features by varying dimensions such as draft angle and aspect ratio.

To determine the effect of fiber alignment on molding outcomes, two variations of the same tool were printed:

These two tools were then processed on Fortify’s 30 ton injection molder using the same exact molding and processing conditions, and feature failures were logged. The results demonstrated significant improvements in tools with the pre-programmed fiber alignment using Fluxprint.

The mold that utilized magnetic alignment of fibers (Fluxprint) exhibited 80% less feature failures than the tool that was printed without Fluxprint. More importantly, difficult features, such as fins and tall extrusions more frequently survived the molding process in the tool that underwent Fluxprint. These difficult features are typically a common failure of 3D-printed mold tools. The tool that was printed with Fluxprint had many of the standing features outlast the tool without Fluxprint

The value of 3D printed mold tools – cost savings, time savings, validating designs, prototyping, etc. – can only be truly realized if the tools can hold up to the harsh conditions of the injection molding. Historically, 3D printed tools have not been able to perform for these low-volume applications – with failures seen as early as the first shot.

By leveraging CKM and Fluxprint – with the preset fiber orientation scheme – Fortify is able to create short-run tools that can process harder plastics with greater tool life.

See the difference for yourself in this video that compares Fortify’s 3D printed mold tools that use Fluxprint compared to other 3D printed parts.