Open source material 3D printing is a hot topic in a hot industry – for good reasons. For Additive Manufacturing is to go truly mainstream, economics must evolve as buyers want power and leverage in their competitive markets.

Can you imagine mature traditional manufacturing segments working with closed material supplies? What if top CNC suppliers required their customers to run only their branded feedstock? Or if injection mold presses ran exclusively with one brand of pellets? These scenarios are unimaginable. Yet in additive, it’s a factor we deal with daily.

Over the past decade, open source systems have made tremendous headway across prototyping, manufacturing aids, and a host of low and moderate performance end use part applications. Filament extrusion (FFF) systems were the first to widely embrace open platforms and lead adoption by a wide margin. This approach has been a huge win as it has dramatically expanded the footprint and impact of our industry.

Pressure towards wider adoption of open systems is intense as major materials companies (BASF, DSM, Corning, Dupont, Henkel, and others) recognize the potential of the additive manufacturing industry and are working aggressively to replicate the strategies that have driven their success in other manufacturing sectors.

However, reliance on closed material systems remains common for more demanding applications, where performance, reliability, and manufacturing grade repeatability are crucial. This is especially true in photopolymer AM modalities (SLA and DLP) and across the board in metals. While there is plenty of innovation around open materials in these spaces, the adoption rate lags.

This evolutionary adoption is driven by factors like complexity of the technology, IP barriers, and rigors of the applications. In many cases it comes down to who “owns” the performance specifications for parts coming off the machines. When parts are out of tolerance (easy but costly to verify) or material properties are inconsistent (difficult AND expensive to verify) the business case for AM can quickly go down the drain.

Innovative high-performance technologies rely on complex material formulations and very specific processing techniques to get consistent results. Hardware, software, and innovative materials must work in perfect harmony. Transitioning these processes to a true open-source environment takes cooperation between machine suppliers, material suppliers, and customers. Until customers are prepared to take responsibility for results, this can’t be achieved. True AM pioneer customers recognize this and staff their teams accordingly. They have the expertise, deep understanding, and an appetite for process verification needed to take advantage of open materials.

Customers with less appetite for this level of expertise and investment benefit greatly when a supplier can provide assurances that the complete ecosystem of systems, materials, and software all work together to the required endpoint. Equipment suppliers need to adopt and communicate their strategy clearly so customers understand the level of support they can expect.

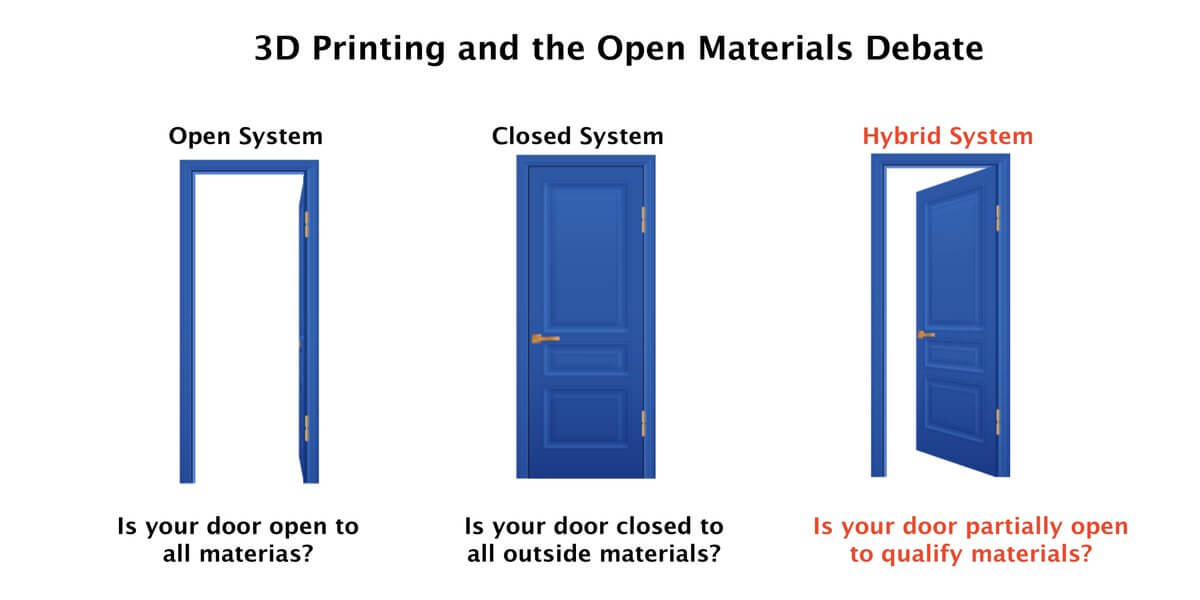

There are different flavors of open source systems. In a fully open platform, the equipment supplier plays essentially no role in the materials side. In a qualified ecosystem, the equipment supplier may pre-load or publish settings for specific materials and provide a higher level of support. Material and equipment companies jointly market and support these solutions to the end customer.

Fortify is pursuing a hybrid approach to our open platform. We partner with leading chemical companies to leverage high-performance base photopolymer resins for 3D printing. We then focus our efforts on selecting and tuning our reinforcing additives and software to enhance specific mechanical, thermal, and electrical properties for end-use applications. This “open mindset” approach allows us to innovate quickly to take advantage of new capabilities to meet customer requirements.

We work extensively with each new material system to ensure it consistently achieves the desired results on our platform.

Despite the hurdles to ensure quality and predictability, customers are increasingly interested in open-source 3D printing systems. As various modalities of AM mature and grow, material systems will standardize, spurring adoption rates at the rapid pace long anticipated.

Simultaneously, innovation in new modes of AM will continue to rely on semi-closed ecosystems as they work their way towards maturity. Suppliers of equipment and materials will choose their strategies carefully as the industry evolves.

If you’re facing challenges finding the right materials for a tough application, maybe a reinforced photopolymer is the answer. As an early adopter of Fortify technology, you gain access to leading material scientists pushing the boundaries of additive manufacturing. We are a tight-knit group of practical PhDs and engineers with deep expertise in combining materials and functional additives to extend the range of material properties. We leverage our relationships with top companies in the business to solve your unique challenges. Our agile consultation/service platform lets us quickly determine the technical fit and economic viability of your application.

If you have an application where current 3D print materials are falling short of your needs, let’s talk. Contact applications@3DFortify.com or get in touch with our applications team.