Written by Applications Engineer Craig Crossley

New environmental regulations are going to require manufacturers to redesign packaging so they are only one material (monomaterial) – which allows for increased ability to recycle as opposed to packaging made from multi-materials. This creates the need for rapid product development in order to completely redesign bottles and caps to be made of different materials than ever before. More companies are leaning on HDPE bottles and caps rather than the traditional PET bottle, which is going to cause a necessary redesign as the mechanical and physical properties of the materials are different.

Along with mono materials, tethered caps and closures are another shift in the world of manufacturing, designed to keep caps with their bottles to decrease the amount of litter made from single-use containers. These types of caps are pushing designers to get creative and develop entirely new caps and closures. This blog is going to give designers, product developers, and industry professionals the proper information for the future of packaging and how to leverage 3D printed tooling to stay ahead of the competition while maintaining proper prototyping procedures.

Mono material packaging is the use of one material for an entire packaging assembly including films, bottles, and other packaging enclosures. Many bottles today are PET with a PP or HDPE cap. While PET is highly recyclable, the need for sorting of the two different materials can make recycling a difficult process. The goal of mono material packaging is to create a streamlined process where a full assembly can be recycled in a single stream without contaminating the recycled resin.

Along with the approach to using a single material for all the different parts of the assembly, the material itself needs to be a single polymer. The use of natural PET, PP, and HDPE is paramount to the success of this approach. Using polymer alloys, additives or colorants contaminate the stream and then require the material to be processed as PCR instead of being able to utilize bottle-to-bottle recycling. PET is highly recyclable, yet once colorants or additives are introduced into the melt, they are nearly impossible to remove, which means it can no longer be recycled with natural PET. Avoiding the use of highly customized colors or grades/alloys of these resins is another piece of the mono material puzzle that allows for direct bottle-to-bottle recycling and streamlining of the waste streams.

There are several major regulatory changes that are promoting the shift to simplify the recycling process and create a truly circular economy. One of these is the EU Directive 2019/904 which requires the use of tethered caps and closures for beverage containers. Below is an explanation of the reasoning behind this directive:

“Plastic closures and lids used for beverage containers are among the single-use plastic items most frequently found as litter on the beaches of the European Union. Therefore, the placing on the market of single-use plastic beverage containers should only be allowed if they comply with certain product design requirements in order to significantly reduce inputs of plastic container closures and lids into the environment. For beverage containers that are both single-use plastic articles and packaging, this is an additional requirement to the basic composition, reusability, and recoverability, including recyclability, requirements for packaging set out in Annex II to Directive 94/62/EC.”

Read more about EU Directive 2019/904 here: https://blog.engelglobal.com/en/us/blog/requirements-for-the-production-of-tethered-caps.html

There are several notable types of packaging that are not affected by this directive which include metal or glass containers with a plastic lid/cap and medical containers. This requirement will take effect in 2024, meaning that the development for all of these new caps and closures will need to be rapid and cost-effective so that companies can still maintain high production throughput without breaking the bank on their product development.

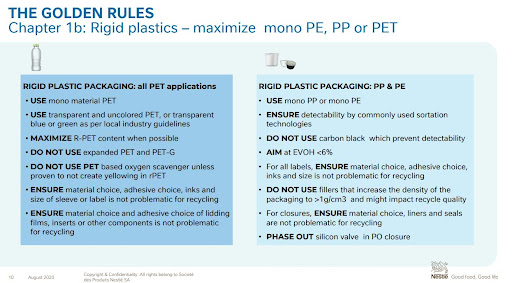

While not a law in most places, mono material packaging is starting to be required by many large companies developing new products. As part of almost every sustainability initiative, it is at the forefront of product development teams all over the world as many scramble to redesign decades-old technology in order to adjust for differences in mechanical properties when using a new polymer. For example, Nestle has laid out very clear guidelines for what their expectations are for implementing mono material products in order to promote sustainability.

These regulations and initiatives are all in order to promote sustainability across organizations so that the amount of waste produced can be reduced and so that plastics as a whole can still be a part of our daily lives, without the need for further bans. So while these are promoting very good ideas and will ultimately be positive for the environment and the plastics industry, many people on the ground floor are feeling the pain. Introducing a new material to a product is not as simple as swapping the material on the production floor. Products are designed often with specific requirements for mechanical, chemical, and physical properties, which in turn lends itself to a specific material. Once a material is chosen the design can be tweaked and finalized with that material in mind. When you introduce a new material into that product, there are changes in the design that are going to need to be made. In order to validate those changes, prototyping and specifically prototype tooling are going to be necessary. Whenever tooling is required, long lead times and large budgets are generally to follow, which slows down the development cycle, and with these regulations and initiatives underway, there is no time for delays. That is why leveraging 3D printed tooling in a prototyping process can speed up sustainability initiatives and allow manufacturers to prototype for the circular economy.

Photo of Fortify Tool in Injection Mold Press

Utilizing Fortify injection molding services can allow product development teams to get molded parts for functional testing in 10 days at a fraction of the cost of hard tooling. This type of speed allows customers to begin their production tool builds months ahead as compared to using aluminum or steel prototype tooling. By using 3D printed tooling, development teams can have the flexibility and agility of additive manufacturing, but the part functionality and material portfolio of injection molding. Instead of getting a PP-like part or a PET-like part, you are able to get an actual molded part. This is imperative for living hinges and blow mold preforms, especially when these products have never been made before, or they have always been made from a different material.

Sustainability is the future of the plastics industry as a whole and is no more present than in the packaging field. Plastics are incredibly versatile and are not going to be eliminated, but the companies that will continue to be successful are the ones that stay at the forefront of technology. The cutting-edge of technology right now is focused on recycling, recycling plastics, and new product designs to simplify waste streams. Fortify enables companies to innovate with a low-risk, low-cost tooling solution that gets functional parts and validates designs, without cutting corners that could end up costing millions in scrapped production.

Contact Fortify to learn more about our low-risk, low-cost tooling solution and get a free quote for your needs.