3D Printing Proves Faster And More Cost-effective Than Traditional Mold Tooling Technologies

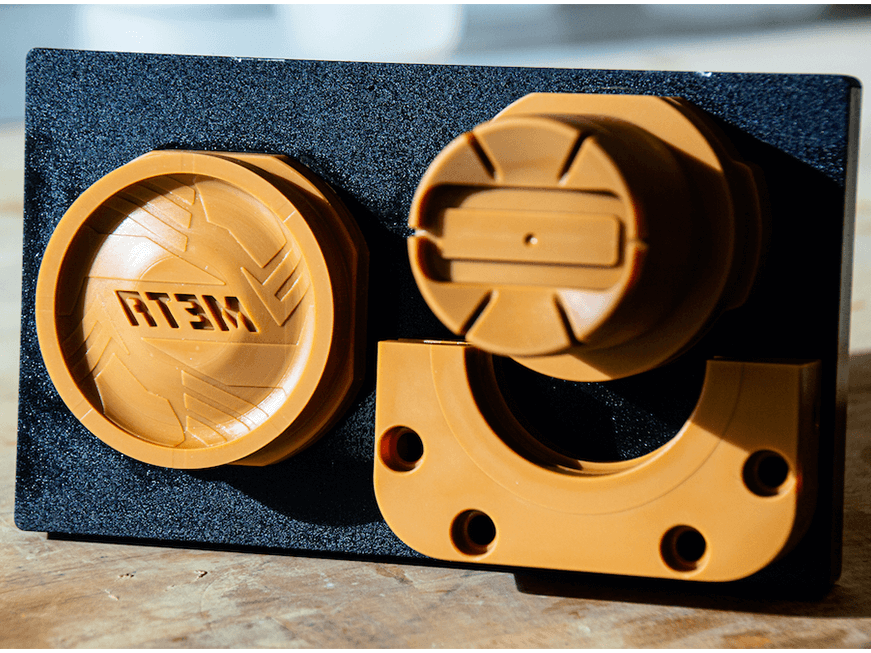

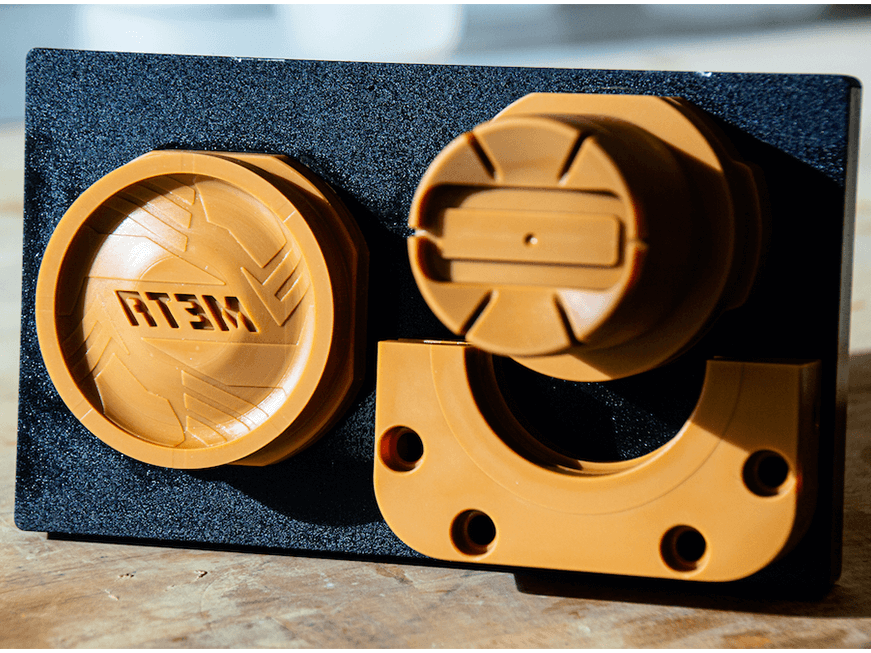

DeMarini Sports, a subsidiary of Wilson Sporting Goods, is one of the many companies feeling the skilled labor pinch. Management there felt that 3D printing might solve the prototyping problem, but quickly realized this would not cover all their bases. Because they had to evaluate the injection-molded materials as well as the finished part design, they needed a fast and cost-effective way to print the actual molds themselves. They turned to Fortify 3D for advice, a digital manufacturing company and developer of the FLUX ONE 3D printer.