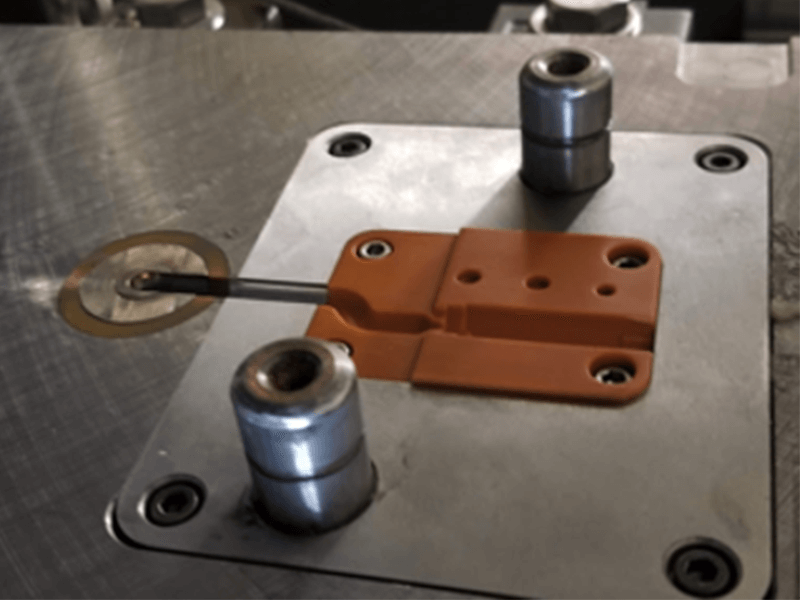

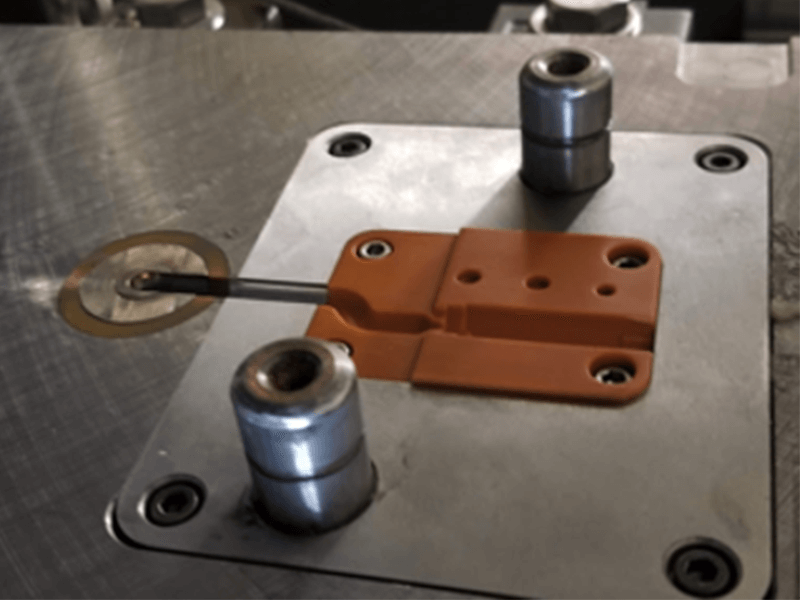

Justifying the economics to prototype metal injection molding (MIM) tools is challenging as it is timely and costly to produce these tools. 3D printed tools save molders time and money, but traditionally have not been able to perform with the abrasive MIM feedstock – an abrasive/polymer slurry. After parts are molded on a press, the green body is sintered to obtain pure metal parts.

Alpha Precision Group (APG), a leading service provider of highly-engineered metal fabrication, offers MIM services to meet many customer needs. APG was looking to incorporate prototyping as a part of the process for their customers to better design for production MIM. 3D printed tools provide the fast and economic value that customers were looking for but failed during the molding process.