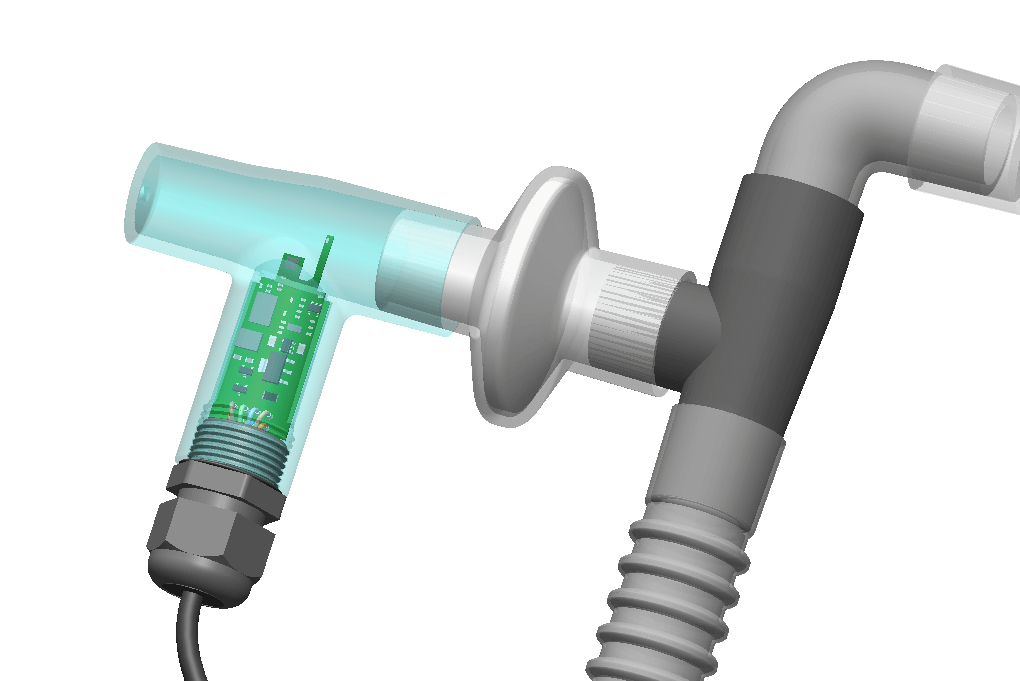

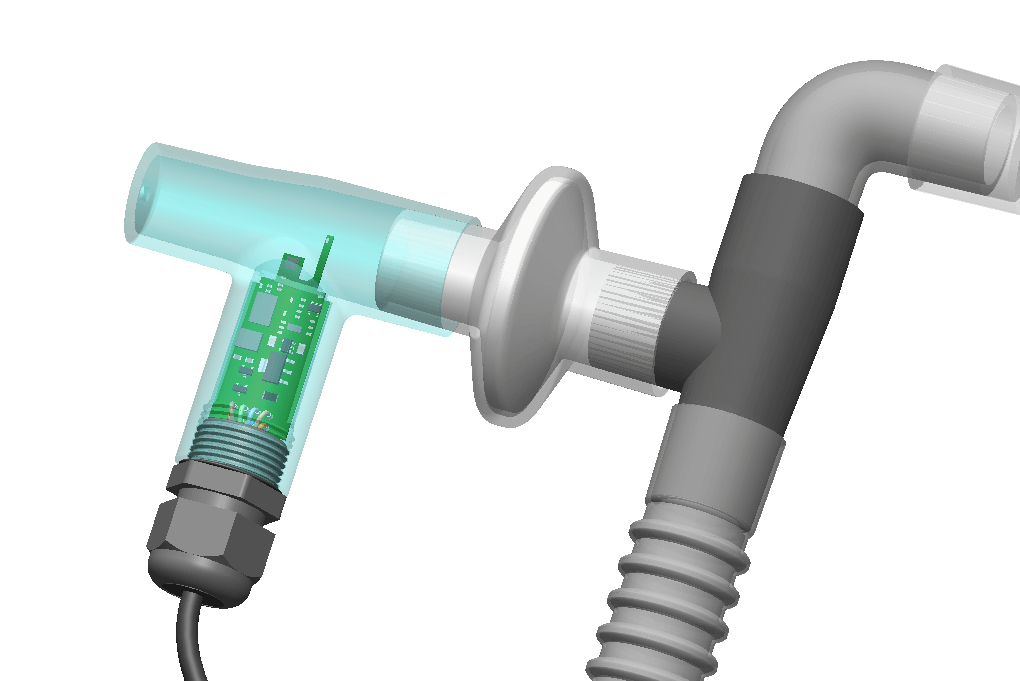

The engineering team from Ventilator Project was racing the clock to design and qualify parts for a COVID response initiative. They needed a set of molded parts to keep their project moving. Fortify used 3D printed tooling to get two designs printed for the customer’s engineering team. Fortify delivered a set of injection molded polypropylene T-splitter components which met the fit, form, and function quality requirements – but more critically enabled the Ventilator Project team to perform validation testing using injection molded polypropylene.