This blog post is the first of a two part series on how nature is inspiring advancements in engineering materials.

Nature is a constant source of inspiration for engineers. Bird feathers, lotus leaves, eggshells, and squid tentacles may not seem like they have much in common, but every natural material has characteristics that are precisely tuned to thrive under specific environmental challenges

In nature, Function Dictates Form, and materials have precise microstructures that enable survival. Bio-inspired materials are the backbone of Fortify’s additive manufacturing solutions. Fortify is hardly alone in leveraging Mother Nature’s powers. Here are some of our (other) favorite innovations occurring today in the field of biomimicry:

1. Squids → Self-healing plastic

Imagine fixing a cracked phone with just a few drops of water. This may soon be possible with ongoing research into squid ring teeth, which contain a protein complex that enables self-assembly and self-healing. This material has incredible benefits for engineering, featuring a high elastic modulus, the ability to form strong bonds underwater, and a fluid glass-to-rubber transition. In a few years, materials scientists may be able to develop a self-healing plastic that makes cracked phones a thing of the past.

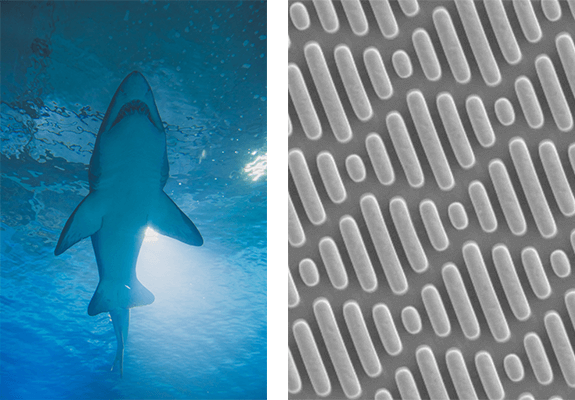

2. Sharkskin → Bacteria-repellent material

While grime can build up on a whale or a sea turtle, parasites simply wash off a shark without taking hold. Sharkskin has a patterned microstructure (above, right) that prevents bacteria from growing (some bacteria prefer smooth surfaces). Scientists at Sharklet Technologies have developed a bacteria-repelling material that mimics sharkskin’s structure, featuring a microscopic diamond-shaped pattern. Soon, this shark-inspired material could make its way into hospitals and public bathrooms, repelling drug-resistant super bacteria like MRSA and saving lives in the process.

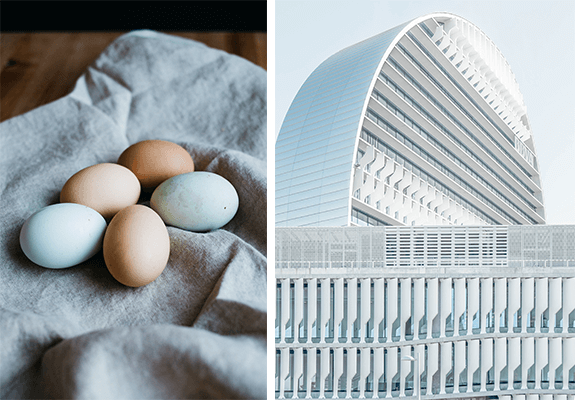

3. Eggshells → Sustainable building materials

The common eggshell is incredibly lightweight yet difficult to crack open, thanks to its specialized formulation of minerals and proteins. Minerals bring stiffness and durability, while protein keeps the shell lightweight. One researcher is studying eggshells and bones to develop sustainable building materials. Because concrete production requires temperatures over 1,000 degrees to produce cement, the concrete industry makes up 10% of global carbon dioxide emissions. Eggshells, however, develop excellent mechanical properties at body temperature. Someday, eggshell-inspired materials may begin to replace concrete and steel, improving the global carbon footprint.

4. Abalone shell nacre → Additive Manufacturing Composites

The mother of pearl (or nacre) has incredible strength-to-weight and toughness properties due to its complex and highly optimized microstructure. The microstructure combines relatively weak base materials in a sophisticated matrix. Materials engineers have studied Nacre for years to understand these natural composites and attempt to replicate their properties.

Unfortunately, these engineers have been a bit stuck as there was no methodology to manipulate the orientation of fibers within a polymer matrix. The Fortify team developed an additive manufacturing platform called DCM (Digital Composite Manufacturing) to solve this problem. This new technology uses magnetics to orient fibers on a voxel-by-voxel basis. Engineers finally have the tools to fabricate custom composite materials with target stiffness, strength, and hardness properties. Learn more about DCM here.

Read the second post in this series here

Read the second post in this series here