ORIGINALLY PUBLISHED ON PLASTICS TECHNOLOGY – Written by VP of Business Development, Ben Arnold

The use of 3D printed injection mold tooling has been discussed, debated, and tested extensively over the past 20 years. Implementation of the technology has steadily gained traction. While the technology is still far from “commonplace,” true innovators have now fully embraced it across many industries.

Even during the current global pandemic, interest is strong and suppliers like Fortify are seeing a rash of new inquiries.

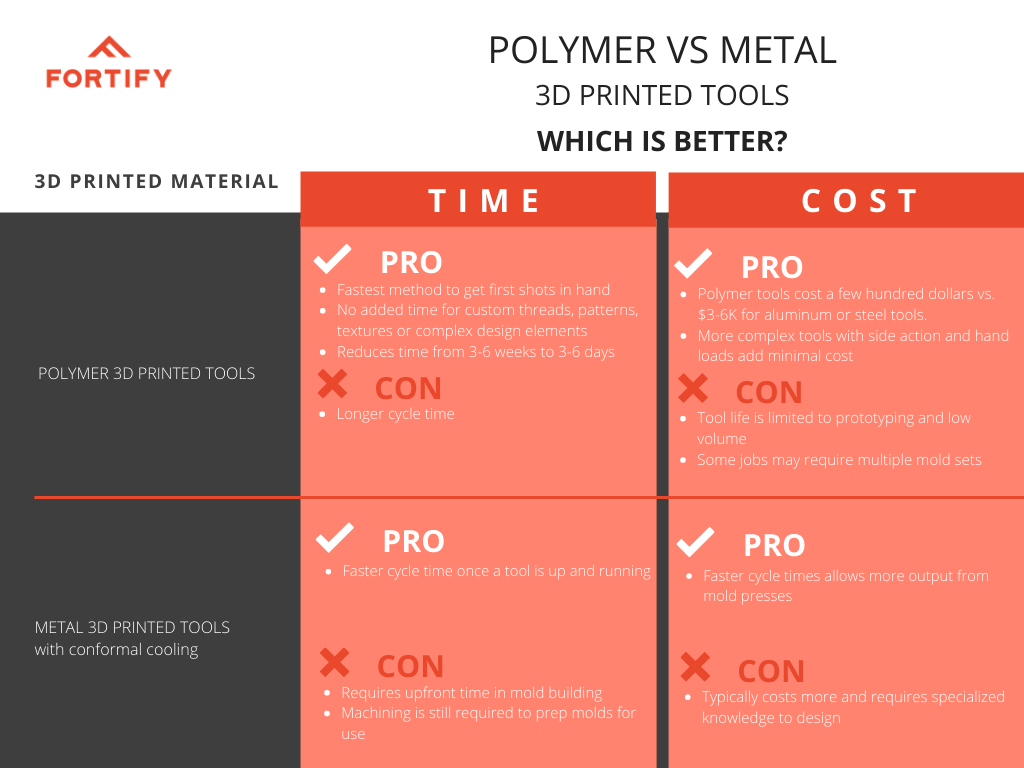

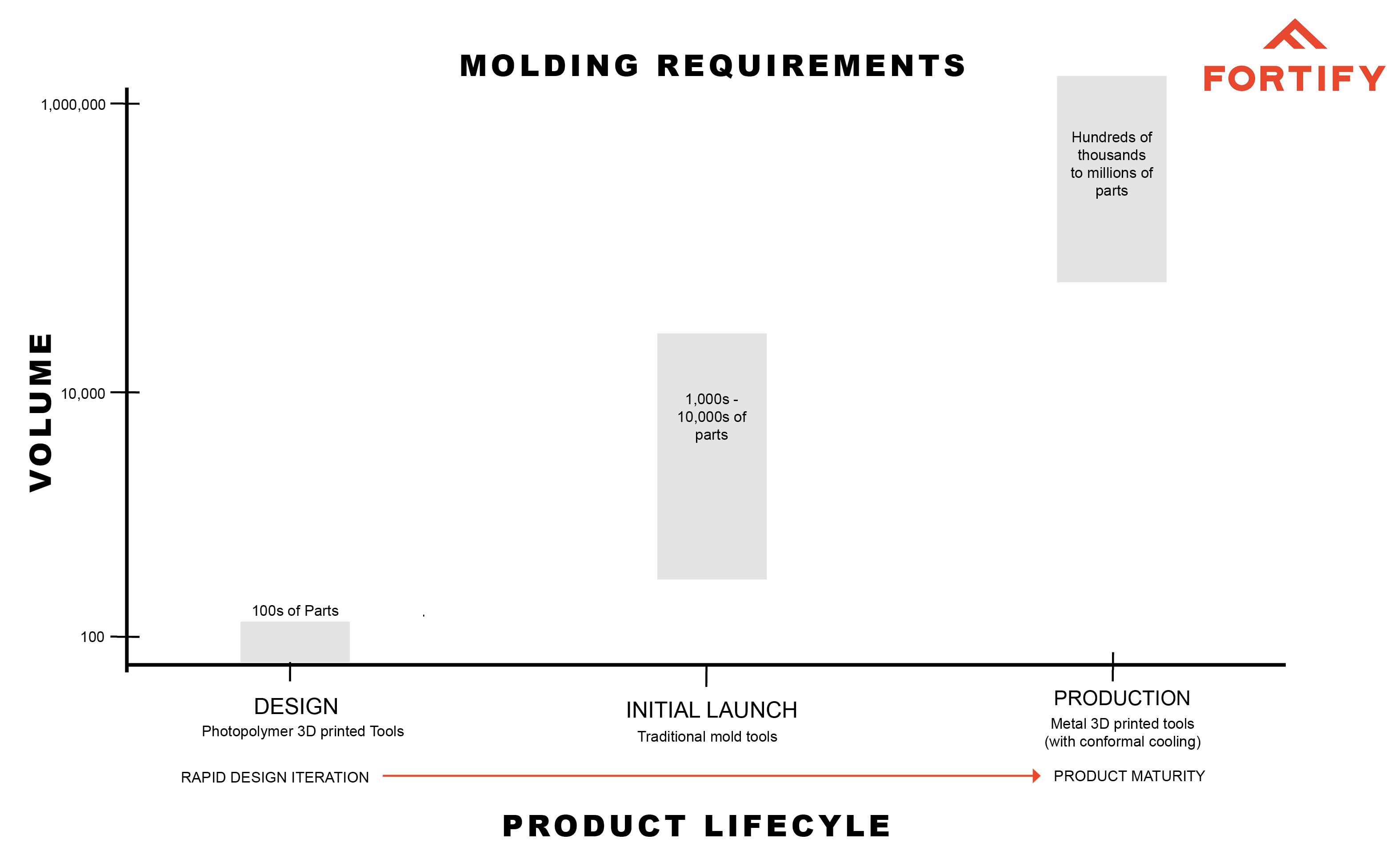

Advances in both metal and polymer 3D printing technologies have helped drive the acceptance of 3D printed tooling around the general themes of lower cost and faster turnaround. A frequent customer question that comes up is, “Which is better?” This article outlines that “better” is the wrong metric. Instead, molders should be looking at the key differences between metal and polymer 3D printed tooling, and where in the product lifecycle each technology fits best. (Spoiler: 3D printed mold tools should be leveraged for prototype injection molding).

Time is Money

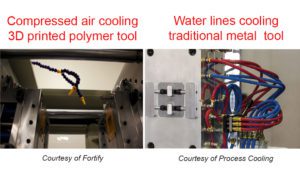

While both technologies offer significant COST and TIME advantages, the way these benefits are calculated is vastly different. Users of polymer-based cores and cavities, focus on the TIME it takes to get first shots in hand. These molds can be printed and run within a few days. Multiple design iterations can be validated within a single week with this approach – essential for prototype injection molding. Users can cut months of time from new product releases. One tradeoff to consider is polymer 3D printed tooling does run longer cycle times as the molds do not cool quickly. These longer cycles are typically acceptable as required part quantities are low during the early prototype stage.

The COST of polymer based 3D printed tooling also has important tradeoffs to consider. Polymer based tools can be printed for 60-90% less than metal (several hundred dollars or less versus $3,000 – $8,000 for metal). While these savings are compelling, tool lifetime needs to be factored in to get a true picture. Metal tools can be expected to last tens or hundreds of thousands of cycles while polymer tool life is typically measured in hundreds of shots.

In early lifecycle stages, when 50-100 parts are needed, this equation is easy to solve.

Polymer 3D printed tools can be outsourced to a service bureau, or produced on in-house equipment for fastest response times. In either case, polymer based tools require some design considerations to get best results. This includes more generous draft angles and venting strategies. A more complete review of designer considerations for using 3D Printed Polymer tools can be found (here.)

Regardless of your sourcing strategy 3D printed polymer mold tools, it’s wise to work with a supplier that has deep technical knowledge of the application and can help you make the right design choices.

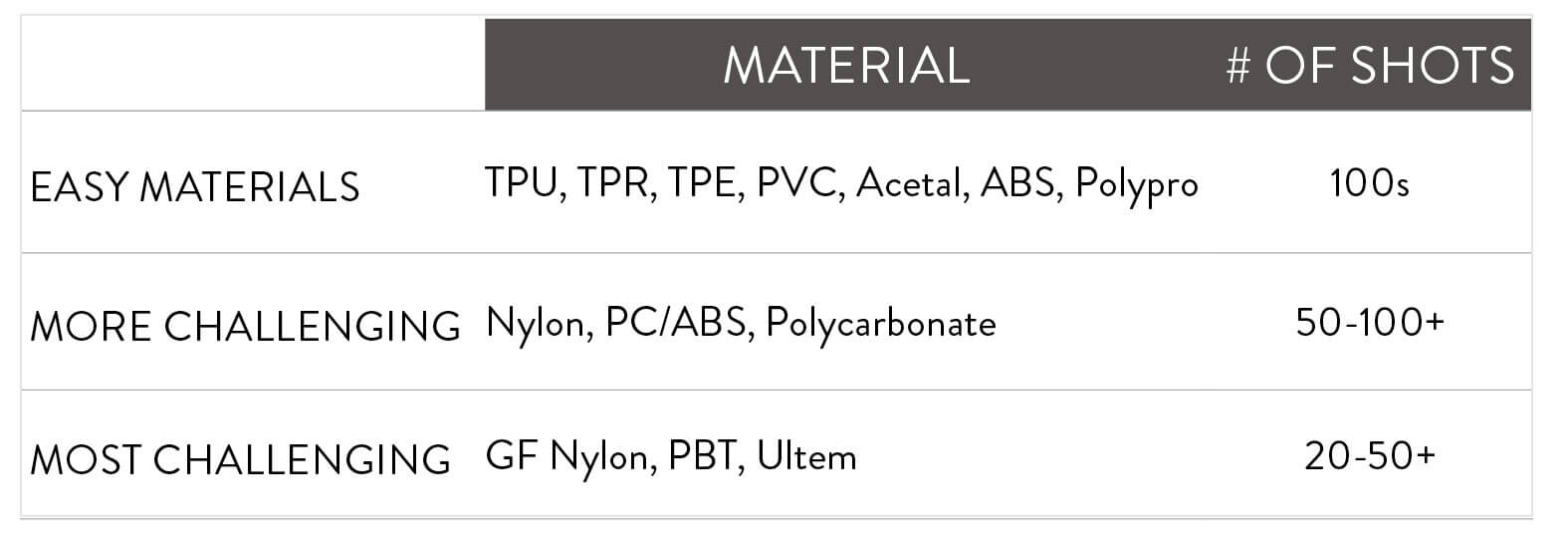

The capital investment for polymer 3D printers ranges from under $10,000 to several hundred thousand. Choosing the right printer is dependent upon build capacity and material properties needed for a specific application. Molding engineering grade plastics like ABS, PCs, Nylons and higher, requires 3D printed mold tooling that is printed with very high performance materials that are not typically available to run on entry level printers.

Courtesy of Fortify. Numbers above represent tools using Fortify Digital Tooling. Other 3D printed polymer tools will have limited materials and performance.

With 3D printed metal tooling, TIME advantages are focused on cycle time and productivity. The key attribute of the metal technology is the ability to fabricate molds with sophisticated conformal cooling channels that allow faster cycle times. This is a natural fit for high volume scenarios where cycle times are critical. Conformal cooling channels are simply not possible to manufacture with traditional machining techniques. Note that conformal cooling benefits do not translate to polymer based tools with their low heat transfer coefficient.

The COST savings associated with metal 3D printed tooling are typically realized on the production floor – not in the building of the tool itself. Metal 3D printers and materials are expensive, and the molds require significant post processing and machining before they can be put into production. Some exciting new technologies are available now that integrate additive and subtractive technologies and help close this gap. Material choices and quality levels of metal 3D printed molds are also trending upward making this option more attractive.

As the mold cost gap between traditional and 3D printed metal tools narrows, the big payoff for using metal 3D printed mold tools continues to be higher press utilization rates. For example, when cycle times are reduced by 20% the press utilization goes up 20%. Molders can get more parts out the door each day with the same capital equipment. More parts shipped = more money and higher customer satisfaction.

The two faces of 3D printed mold tooling don’t actually compete – rather they compliment each other as products make their way from concept through maturity.

Conformal cooling design is not practical at the prototype injection molding stage when designs are still evolving. Likewise, polymer based tools, with longer cycle times and limited life are not a practical solution for volume production.

One theme that is consistent with both technologies is they both require an investment and commitment on the part of the molder to learn how to best leverage the technology. This is the basis for building a sustainable competitive advantage in the market.

At Fortify, we are focused on raising the bar for 3D printed polymer tooling by incorporating reinforcing fiber to the material. These tools can withstand “challenging materials” to provide plenty of shots for prototype injection molding

SUMMARY OF METAL VS POLYMER 3D PRINTED MOLD TOOLING