What is GRIN?

Conceptually, a microwave lens is similar to an optical lens. However, instead of light, the lens is designed for the manipulation of microwaves. While a homogeneous lens antenna has a uniform index of refraction and discrete refraction at the lens-air interfaces a GRIN lens has a varying index of refraction and continuous refraction throughout lens body. The varying index in a GRIN lens allows the rays to refract throughout the entire body of the lens, while a homogeneous lens only allows refraction off the surface. This varying index allows for a variety of benefits around SWAP-C, field-of-view, and design freedom.

At Fortify, we utilize material science combined with our expertise on the unit cell design, to create GRIN lenses for use in mmWave beam forming applications. By utilizing the lattice-based design, we are able to create the desired dielectric gradient needed for your application. Previously, manufacturing techniques for GRIN lenses were limited to expensive lenses made out of a limited amount of materials, with limited design options. But with Fortify’s materials and manufacturing methods, lenses are cost effective, lighter weight, and can be made in a variety of shapes.

Why GRIN?

Wider Field of View

By correcting aberrations at the focal plane, the lens can enable a wider field of view

Reduced Weight

Due to their range of index values, GRIN lenses can be made extremely thin and lightweight. When combining this geometry with Fortify’s materials, you can get a GRIN lens lighter than other traditional lens manufacturing materials, such as Rexolite.

Freedom of Design

The nature of GRIN lenses and their ability to be of arbitrary shape, as well as Fortify’s innovative manufacturing platform, allows for complete design freedom and the ability to have a wide variety of geometries for a lens.

True Time Delay

Most often GRIN devices are true time delay which allows for extremely wide instantaneous bandwidth.

Engage with Us

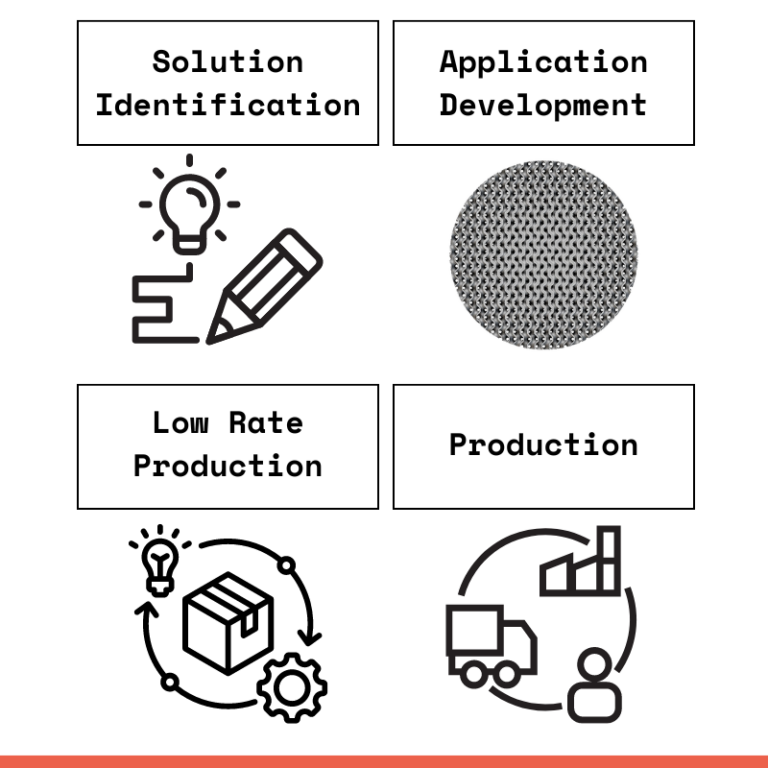

From solution identification to production, Fortify has the process and expertise to mature your application across it’s lifecycle

Resources

Videos & Webinars

WEBINAR: Insertion Loss of 3D Printed Selectively Metallized Microstrip Circuits on Low-Loss Dielectric with Varied Surface Roughness

WEBINAR: How to Design and 3D Print a Radar Target Using Low-Loss Gradient Dielectrics

WEBINAR: Development of a 3D Printable Photopolymer for RF Applications

Application Highlight: 3D Printing Low Loss RF Devices

White Papers & Case Studies

White Papers

Overcoming Size Limitations The RF Impact of Segmentation and Assembly on 3D Printed Luneburg Lenses

Greater Design Flexibility with Selectively Metallized 3D Printed RF Ceramics

3D Printed Dielectric Lenses Increase Antenna Gain and Widen Beam Scanning Angle

Applications Guide

Case Studies

Menlo Micro Alleviates Product Design and Test Feedback Cycle Bottlenecks with Low-loss Dielectric Fixturing

Joining Disparate 3D Printing Effective Media: Behaviors in X and Ka Bands

Additively Manufactured eBand Dielectric Lenses are Changing Automotive Sensing

Ku-band/Ka-band Simulation & Testing of a 3D Printed Dielectric Lens Fabricated from Low-loss and Los-dk Resin

Literature & Guides

Insertion Loss of 3D Printed Metallized Microstrips

RF Application One Pager

Field of View Lens One Pager

RF Applications Guide

Articles

Benefits of Using 3D Printing for Low-Loss Applications in RF

Dielectric Resonator Antennas (DRA): Applications, Design, & Fabrication Methods

Interview: How Radix™ Dielectric Materials Are Improving RF Components

Insertion Loss of 3D Printed Metallized Microstrip Circuits on 30 MIL Substrates Using Rogers Radix Low-Loss Dielectric with Varied Surface Roughness

The Importance of Surface Finish on Low Loss Performance

Efficacy of Different Test Methods for Low-Loss Dielectrics

Rapid Review 2022: Living in a Material World

State-of-Technology Update On GRIN/Luneburg Dielectric Lenses/Antennas for Microwave/mmWave Applications

Top Factors in Successful Additive Manufacturing Applications

Recent News

Fortify Awarded U.S. Army Contract to Revolutionize Tactical Communications with 5G GRIN Lens Technology

Fortify Delivers Flux One 3D Printer to NASA’s Glenn Research Center

Press Release: Fortify and Rogers Corporation Partner to Develop 3D Printed Dielectric Material Systems for Radio Frequency Devices

What will you Fortify?

Explore what’s possible with us.